-

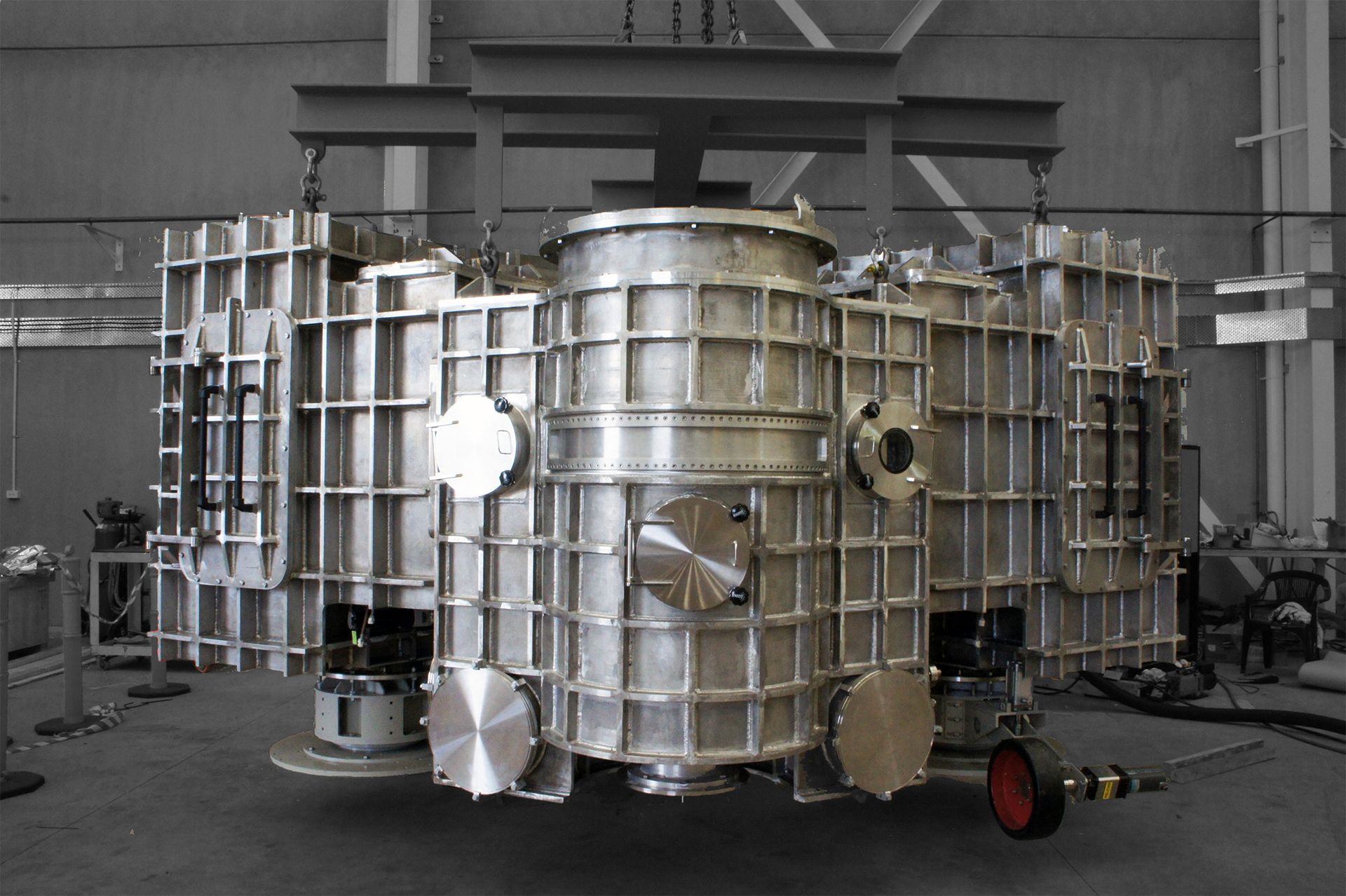

Pharmaceutical, Scientific & Aerospace

NEPEAN Engineering & Innovation’s specialist teams will manufacture and manage small to large-scale projects for the pharmaceutical, scientific and aerospace industry.

Our team’s technical expertise and project management skills ensure we deliver quality output.

NEPEAN Engineering & Innovation partner with Australia’s most progressive suppliers to provide robust, innovative and high quality precision engineering and custom manufacturing solutions.

Pharmaceutical & Scientific specialised equipment includes:

- Hot cell design

- Manufacturing for processing of raw and waste materials

- Special purpose handling equipment for radioactive applications

- Medical screening equipment

Aerospace includes:

- Precision machined items & componentry

- Mr550fmv dual shield ring mount

- Aircraft wing support trestles

- Portable cargo access stairs

- Cradles and transport trailers of jet engines

- Tooling for Orion aircraft

- Assembly jigs and fixtures

- Tooling for composite parts

- Layup mandrels

- Rout fixtures

- Shipping containers for boeing 777 elevators

- Aircraft thrust test fence

Capabilities include:

- Light to heavy fabrication

- CNC milling and boring up to 12m

- CNC turning

- EDM wire cutting

- Spray painting and powder coating

- Spark eroding

- Jig grinding

- Surface grinding

- Cylindrical grinding

- Laser and profile cutting

- Shot blasting, spray painting and powder coating

- Plate rolling

- Pressing and bending

- Sub-arc, mig and tig welding

- Precision inspection capabilities with Leica Laser Tracker at 901

- Special purpose design of components and complete systems from concept to shop drawings for manufacturing

- Precision machining

- Working with special alloys and inorganic materials

- Complete workshop factory acceptance testing followed by on site commissioning